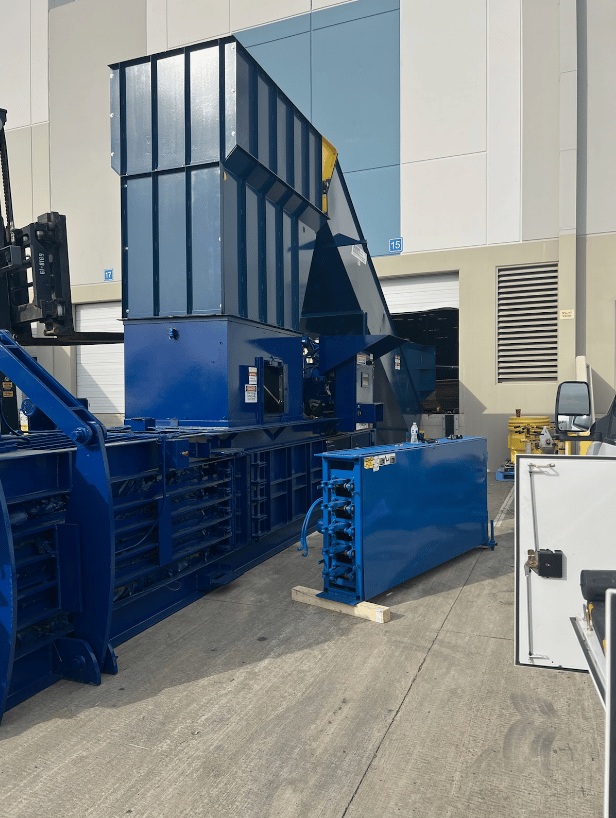

Case Study: Cardboard Baler Cost and Emissions Savings

This case study comes from Ben Sparks, out of our Oakland recycling location:

“Green Planet 21 is installing an auto-tie baler at a large supplier (they asked not to be named, but they make parts for Tesla so they’re very busy). They have been using 2 cardboard compactors, 3 days/week each, for about 26 loads per month. By baling, they will reduce their freight to 3 flatbed loads per month. This results in a freight savings of $11,615 per month, which is almost 3 times the cost of the monthly baler lease payment. That’s pretty good on its own, but I also calculated the reduction in CO2 emissions as it relates to their cardboard recycling program.

To calculate CO2e, the EPA recommends a factor of 161.8 grams per ton-mile. A loaded rolloff truck weighs 28 tons, and a loaded flatbed is 40 tons, so its not quite a straight-line calculation on 26 trips vs 3. The round trip is 65 miles. Once you’ve multiplied all the ton-miles per gram, you divide by 1,000,000 to convert from grams to metric tons.

I found that their current system is producing 90.45 metric tons of CO2e per year. The new system will produce 14.91 metric tons. So by changing from compacting to baling, they’ll reduce cardboard-recycling related carbon emissions by over 75 metric tons per year. “